AI-BASED QUALITY CONTROL IN SMEs

GUIDELINES FOR THE DESIGN, IMPLEMENTATION AND USE OF QUALITY INSPECTION FOR TEXTILES

Artificial Intelligence (AI) quality control can help small and medium-sized enterprises (SMEs) enhance their production and service quality, boosting competitiveness. This guide supports SMEs in implementing AI-based quality control and assists developers of such systems.

The focus is on human-centered design, implementation, and use of AI quality control in SMEs, emphasizing ergonomics in human-system interaction. The guide follows DIN EN ISO 9241-210 “Ergonomics of human-system interaction – Part 210: Human-centered design for interactive systems.” Technical aspects can be addressed using additional guidelines and standards.

A selection of possible standards and guidelines:

- VDI/VDE 2206 – Development of Cyber-Physical Mechatronic Systems (CPMS)

- VDI 2221 – Development of Technical Products and Systems

- VDI 3714 – Implementation and Operation of Big Data Applications in the Manufacturing Industry

- Guide for Implementing Smart Factory Concepts

This approach recognizes the unique challenges and requirements of SMEs when adopting AI-based quality control systems. The VDI 3714 guidelines offer complementary insights on implementing data-driven solutions in industrial settings, which can be particularly helpful for SMEs navigating the complexities of AI and big data applications in quality control processes.

This project was funded by the Federal Ministry of Education and Research under the funding codes 01IS21049A, 01IS21049B and 01IS21049C.

The responsibility for the content of this publication lies with the author.

Funded by

Context of Use

The “Understanding and describing the context of use” phase is an essential step in the human-centered design process for AI-based quality control systems in SMEs. The aim of this phase is to gain a comprehensive understanding of the environment, the users and their tasks in which the system is to be used.

Various methods can be used to gather information, such as interviews with users and stakeholders, observations in the workplace, analysis of documents and existing systems, and workshops with the parties involved. The activities presented below are carried out by various stakeholders.

The following aspects should be taken into account:

1. User Analysis

- Primary user groups must be identified (e.g. quality controllers, production managers, technicians)

- The knowledge, skills and experience in dealing with quality control systems and AI technologies of these primary user groups must be recorded

- Possible limitations or special needs of the users must be identified and taken into account

2. Task Analysis

- The current quality control processes and tasks must be described

- Identify challenges and potential for improvement in existing processes (for example, using the recommended procedure according to the guidelines for the implementation of smart factory concepts mentioned at the beginning)

- The objectives and expected results of AI-based quality control must be described in a specific, measurable, acceptable, realistic and timely manner.

3. Technical and Physical Environment

- The existing IT infrastructure and technical resources of the SME must be described, as well as

- The physical working environment in which the system is used

- Possible restrictions or special features of the production environment

4. Organizational Context

- The corporate structure and culture of the SME must be understood by all parties involved (especially solution providers and other external parties)

- Relevant stakeholders and their expectations of the system must be identified

- Legal and ethical aspects of AI use in quality control must be recorded

5. Data Analysis

- Available data sources and formats for AI-based quality control must be recorded

- Evaluate the quality and quantity of available data

- Possible data protection and data security requirements must be formulated

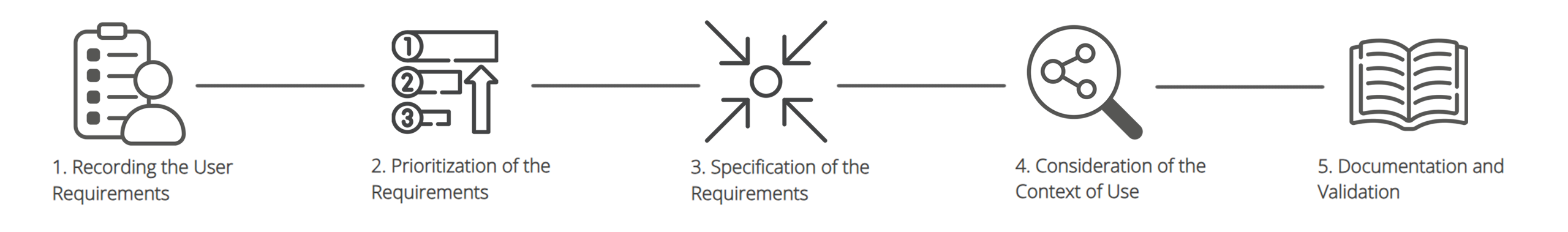

Specifying User Requirements

This phase is crucial for the successful development and implementation of an AI-based quality control system that meets the needs of the users and the company. The aim is to define clear and precise requirements that serve as the basis for the design and evaluation of the system.

1. Recording the User Requirements

- The goals that users want to achieve with the AI system must be recorded.

- The requirements that must be met in order for users to achieve their goals must be described.

- The requirements must be described from the user’s perspective without specifying technical details.

2. Prioritization of the Requirements

- The importance of each requirement for the success of the business must be assessed.

- Determine the technical feasibility and available resources.

- Derive a prioritized list of usage requirements.

3. Specification of the Requirements

- The requirements must be listed in detail.

- The requirements should comply with the quality criteria of ISO 9241-210:

- Measurability

- Free of contradictions

- Completeness

- Feasibility

- Verifiability

4. Consideration of the Context of Use

- Information about users, tasks, work equipment and organizational framework conditions should be included.

- Specific requirements of SMEs, such as limited resources or special industry requirements, must be understood and taken into account by all parties involved.

5. Documentation and Validation

- Structured documentation of the user requirements must be created.

- The requirements must be validated together with the stakeholders involved and potential users.

- The fulfillment of the requirements with regard to the needs and expectations of the users must be checked.

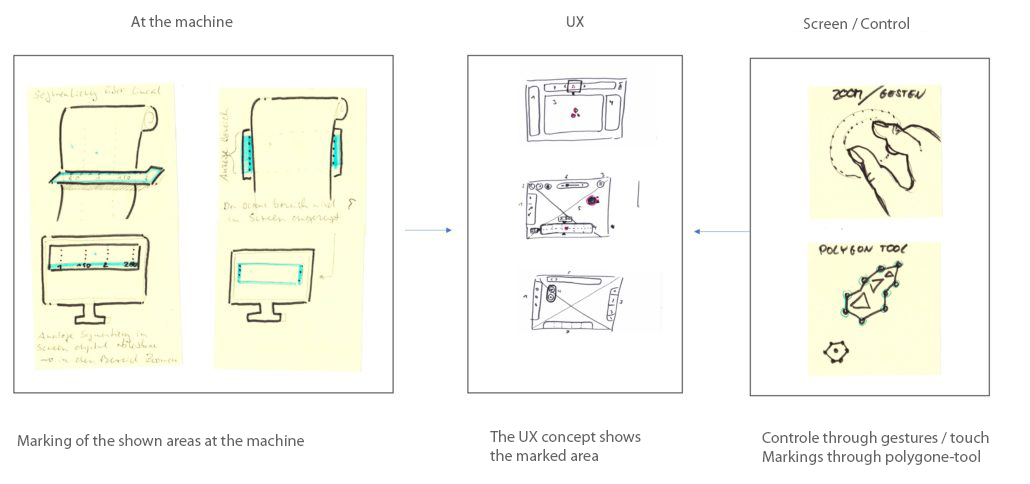

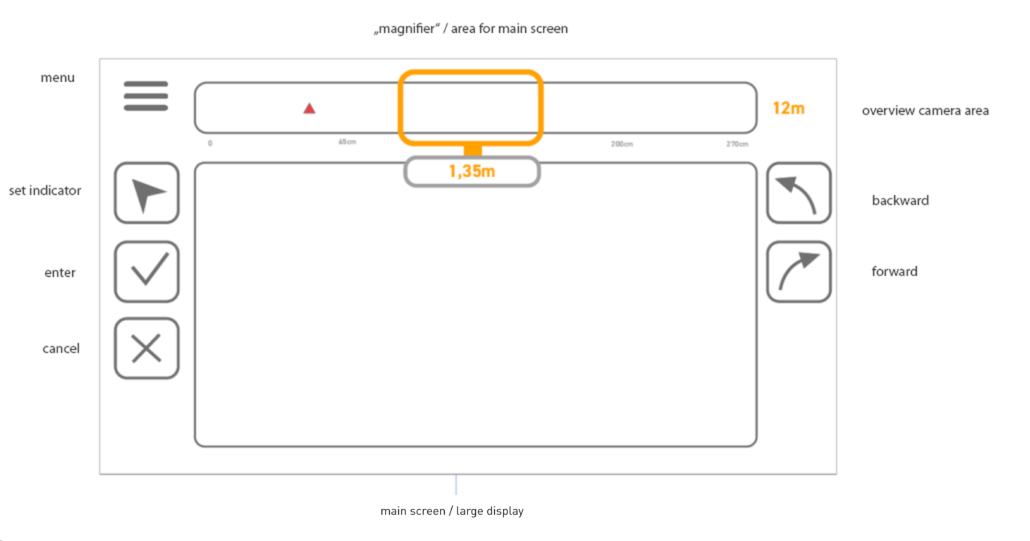

Developing Design Solutions

The aim of this phase is to develop concrete design solutions based on the previously determined usage requirements and an understanding of the usage context. To design the technological aspects of the system to be developed, individual steps can be carried out in accordance with the guidelines VDI 2221 (Methodology for the development and design of technical systems and products) and VDI 2206 (Development methodology for mechatronic systems):

1. problem analysis and requirements definition (VDI 2221)

2. create functional structure (VDI 2221)

3. develop principle solutions and module structures (VDI 2221)

4. domain-specific design (VDI 2206)

5. system integration (VDI 2206)

6. property validation (VDI 2206)

In this phase, it should also be noted that the development process corresponds to an iterative approach. This means that the design solutions developed should be continuously evaluated and adapted. This corresponds to the cyclical approach of ISO 9241-210 and enables a gradual improvement of the system.

Documentation

All decisions and justifications for certain design solutions should be carefully documented. This facilitates later adjustments and helps with the traceability of the development process.

Evaluation of the Design

The design evaluation phase serves to ensure and continuously improve the usability and suitability of the system.

The following aspects should be taken into account:

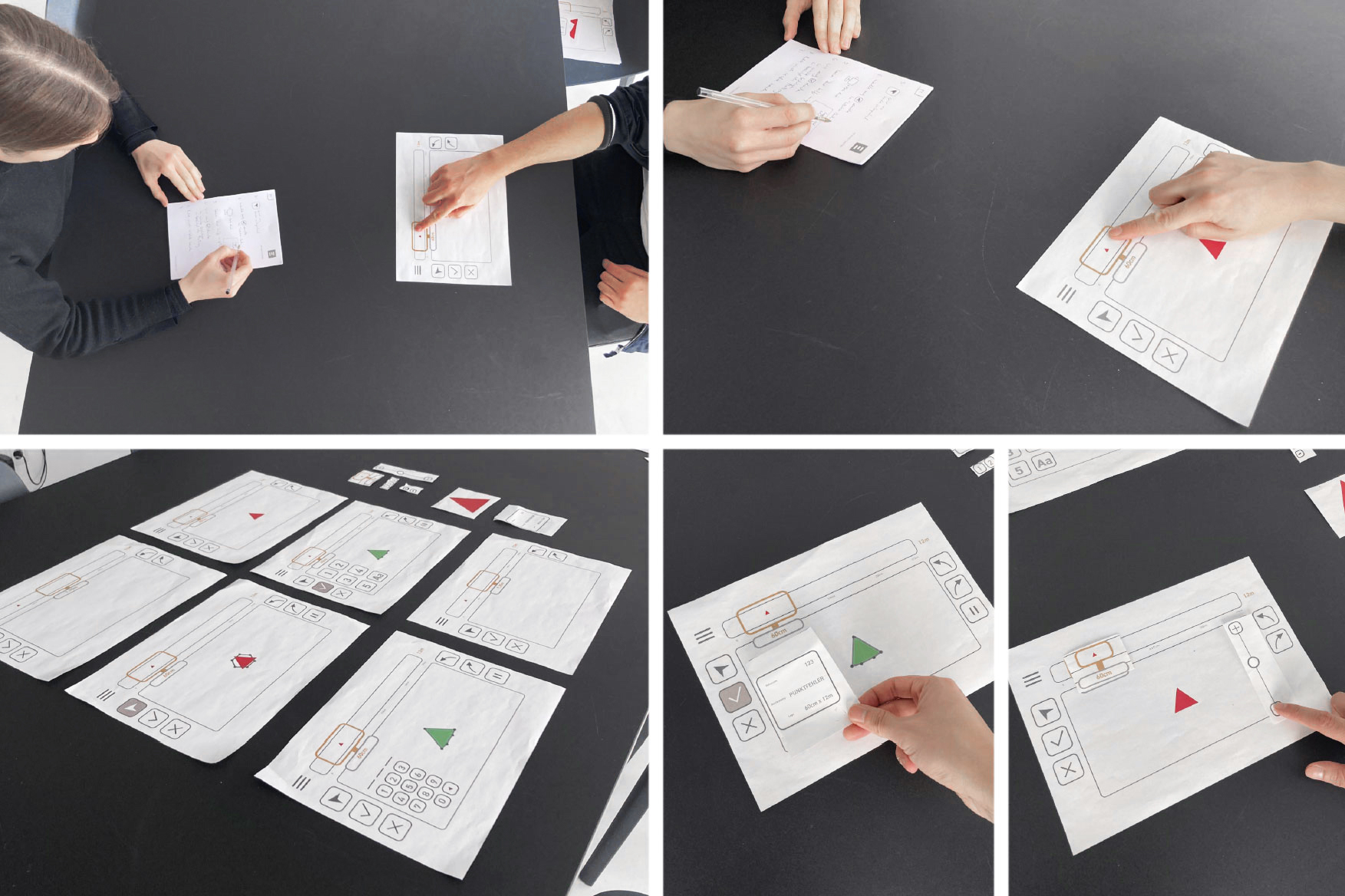

1. User-Centered Evaluation

- Usability tests should be carried out iteratively with employees from quality control

- Obtain feedback on the user interface and usability of the AI system

- User interaction with the system must be analyzed in real work situations

2. Evaluation Methods

- Combinations of different evaluation methods such as observations, interviews and questionnaires can be used

- Eye-tracking or think-aloud protocols can be used as technical tools to analyze user interaction in detail

- A/B tests to optimize the user interface can provide further insights into the fulfillment of user requirements

3. Review

- Ensure that quality inspectors and production employees are included in test scenarios

- A simulation of realistic quality control tasks to evaluate AI support should be provided

- The collection of quantitative and qualitative data on system performance and user satisfaction is required

4. Inspection-Based Evaluation

- Conducting expert reviews to check compliance with usability guidelines can be helpful

- An analysis of the AI algorithms with regard to transparency and traceability by external experts can create security

- Checking the system architecture for scalability and adaptability is helpful for a broader implementation of the developed solution during the usage phase

5. Long-Term Monitoring

- The implementation of mechanisms for the continuous collection of usage data can be helpful, provided that this is feasible in terms of data ethics

- Regular evaluation of system logs and error messages as well as conducting follow-up interviews to determine long-term user experiences can provide long-term insights into possible need for adaptation over the duration of the usage phase

When evaluating the design

the following aspects should also be taken into account:

– Interdisciplinary collaboration: Involvement of experts from the fields of AI, quality control and usability

– Systemic thinking: Consideration of the AI system in the overall context of quality control and production processes

Ethics

Particular attention should be paid to the ethical aspects of AI application, including data protection, fairness and transparency of decision-making. The evaluation should also consider the impact of the AI system on work processes and employee wellbeing. By consistently applying these evaluation principles, SMEs can ensure that their AI-based quality control systems are not only technically efficient, but also user-friendly and ethical. This promotes the acceptance and effective use of the technology in day-to-day business.